The composite products developed and made by Crossfire are totally solvent free and do not release VOCs. Their end-of-life parts, as well as their manufacturing scraps, based on both Crosspreg® and Tricap, can be recycled by mechanical grinding and further compounding into thermoplastic polymers for subsequent injection usage. Even sandwiches made with Crosspreg® or Tricap and PET core can be recycled by grinding them whole, without the need to separate the components. The recyclability of the products has been tested and demonstrated at our partner chemical company, Samyang Corp R&D Laboratories (statement available on request).

Crosspreg® is a reactive prepreg that is stable at RT and features a very long shelf life.

Crosspreg® and CrossLam products are low-energy consuming and, as a result, very competitive in terms of price. Both are industrially produced.

The main driver of both Crosspreg® and CrossLam is their high suitability for series production by means of isothermal press moulding. The transformation time can range from seconds to minutes, making it a low energy-consuming technology.

Crosspreg® and CrossLam represent the green answer to traditional steel technology, which demands high energy use from when the raw material is created to its final transformation.

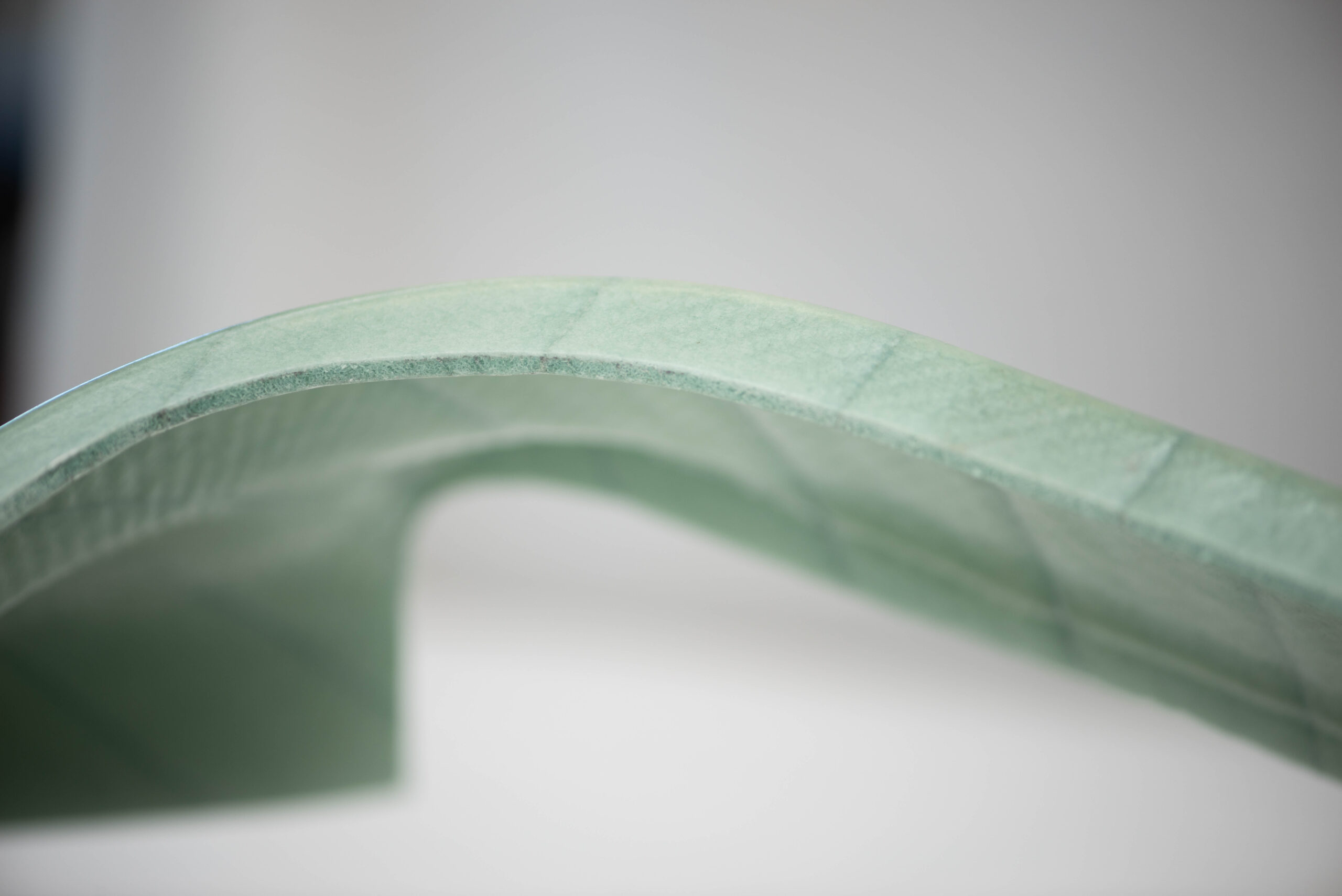

Crosspreg® and CrossLam make it possible to manufacture lightweight structural parts without compromising mechanical specifications. Furthermore, thanks to Crosspreg® and CrossLam engineering, fibre orientation is not isotropic, and a part’s FEM design is determined by the actual stress orientation and intensity.

Products made with Crosspreg® and CrossLam meet 3 fundamental needs:

- Manufacturing using low capital-intensive lines;

- Scaling up economy to highly-competitive finished products (in terms of cost) as opposed to steel-based items;

- Making lightweight products that are sturdy, rust-proof, and longer-lasting, when compared to current standards (structural panels for construction, furniture, containers, shaped items, marine use, etc.).

Crossfire Services

At Crossfire, we develop and start up new technologies based on both in-house and customer ideas. We offer consultancy for composite technologies and their usage, as well as internally design, develop and test new prototypes to verify and measure mechanical and finishing characteristics to ensure that they fully meet the customer's needs.

Crossfire supports the customer in choosing and designing production lines, based on the desired result.

Crossfire is honoured to be partnered with Ormamacchine Spa, a leader in the production of Hydraulic Presses. The company is able to support Crossfire in designing lines based on customer drawings and customising them to the fullest extent.

.

Italiano

Italiano